The Impor filter bag tance of Filter Bags in Filtration Processes

Filter bag, Screen bag, Sieve bag, Separator bag, Filtration bag, Purification bag

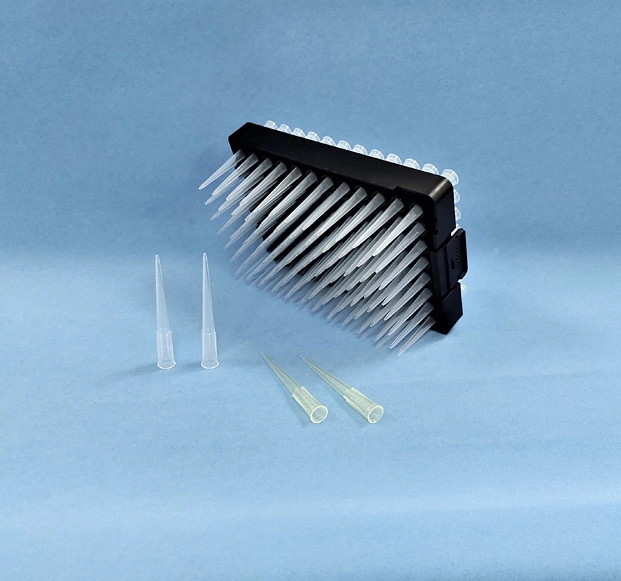

filter bags are essential components in various filtration processes across different industries. These bags are designed to capture and remove unwanted particles from liquids and gases, ensuring the quality of the final product. filter bags can be used in a wide range of applications such as wat

er treatment, chemical processing, food and beverage production, pharmaceutical manufacturing, and many more.

Manufacturing Process:

filter bags are typ

ically made from materials such as polyester felt or polypropylene mesh. The manufacturing process involves cutting the material into the desired shape and size before sewing or welding it together to create a strong and durable filter bag. Some advanced filter bags may also include additional features such as antimicrobial coatings or el geogrid for retaining walls ectrostatic properties for enhanced filtration efficiency.

Characteristics:

Filter bags are known for their high dirt-holding capacity, excellent chemical resistance, and long service life. They can effectively remove contamin Drainage geonet ants of various sizes without clogging or compromising the filtration process. Additionally, filter bags are easy to install and replace when necessary.

Advantages:

The use of filter bags offers severa Separator bag l advantages over other filtration methods. They provide consistent performance, reduce maintenance costs by extending equipment lifespan; ensure product quality by removing impurities efficiently; contribute to environmental sustainability by reducing waste generation.

Usage Method:

To maximize the effectiveness of filter bag filter bag s follow these steps: 1) Select the appropriate type of filter bag based on your specific application requirements; 2) Install the filter bag correctly according to manufacturer guidelines; 3) Monitor pressure differentials regularly to determin Screen bag e when a change is required;4 ) Replace used filters promptly with new ones;

How to Choose this Product?

When selecting a suitable filter bag consider factors like operating temperature range chemicals bei filter bag ng filtered flow rate requirements durability expectations budget constraints It’s advisable consult with an expert supplier who can recommend customized solutions tailored specific needs

Sieve bag

In conclusion,

filterbags play a crucial role in maintaining operational efficiency minimizing downtime preserving product integrity protecting employees’ health safety Moreover they offer cost-effective solution dewatering treatments effluent disposal complying stringent regulatory st Composite Drainage Network andards Invest high-quality reliable filters today reap benefits tomorrow