Title: The Versatile Filter Bag: A Comprehensive Guide

Filter bag, commonly used in various industries for filtratio geogrid for retaining walls n purposes, plays a crucial role in ensuring the quality and efficiency of processes. Purification bag, Separator bag, and Sieve bag are all types of filt Purification bag er bags that serve specific functions based on their design and material composition. When it comes to choosing the right filt Sieve bag er bag for your application, understanding the manufacturing process, features, advantages, usage methods, and selection criteria is key.

Manufacturing Process:

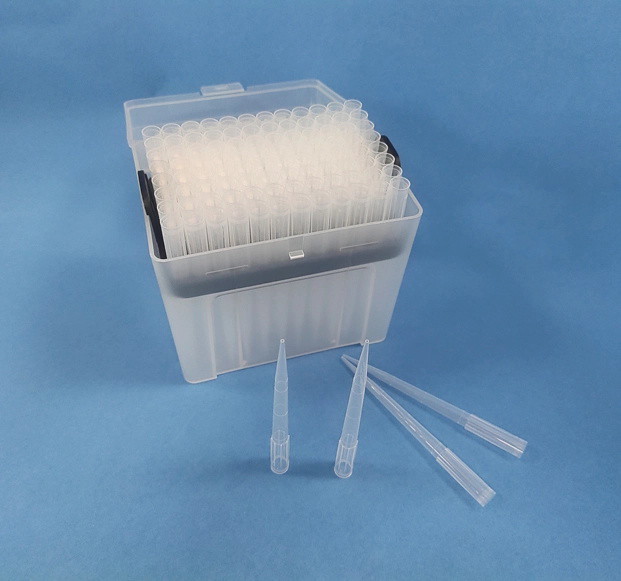

Filter bags are typically made from synthetic materials such as polyester

or nylon. The manufacturing process involves weaving or knitting these materials into a p filter bag orous fabric that allows liquid to pass through while capturing solid particles.

Features:

– High filtration efficiency

– Durable construction

– Resistance to chemicals and high temperatures

Advantages:

– Improved produc

t quality

– Increased production efficiency

– Cost-effective solution for filtration needs

Usage Methods:

Filter bags can be used in various filtration systems such as water treatment plants, industrial processing units, and environmental protection pr Composite Drainage Network ojects. They a Separator bag re easy to install and replace when needed.

How to Select the Right Filter Bag:

When choosing a filter bag for your specific application, consider factors such as particle size to be filtered, flow

rate requirements, chemical compatibility with process liquids, operating temperature range, and durability under pressure.

Conclusion:

The versatility of filter bags makes them indis Drainage geonet pensable in industries where efficient filtration is essential. Whether you need a Purification bag for fine particle removal or a Sieve bag for coarse filtration tasks – understanding the charact filter bag eristics of each type will help you make an informed decision. By considering the manufacturing process details along with features like permeability rating and micron retention cap filter bag ability – selecting the right filter bag can significantly improve your overall operational performance.